SOMA – Die cutters – Bulldog

The Bulldog machine is a roll-fed die cutter mainly designed for the production of foil lids for yogurt containers. The die cutting technique is of very high precision to ensure perfect edge quality. The long life die cutting tool consists of mult...

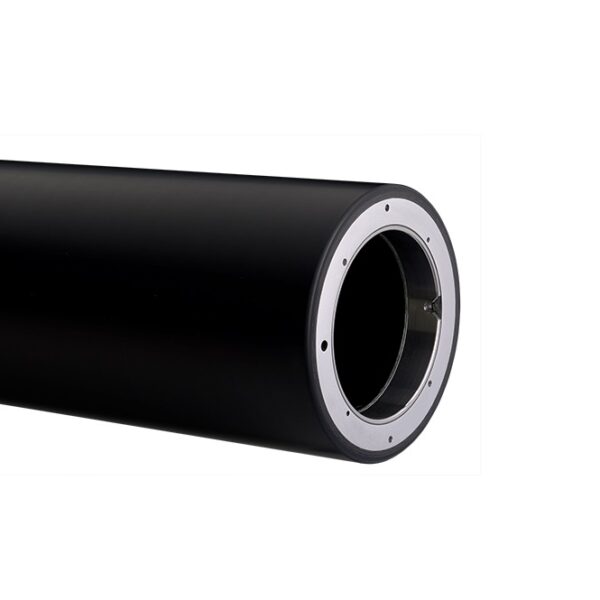

The Bulldog machine is a roll-fed die cutter mainly designed for the production of foil lids for yogurt containers. The die cutting technique is of very high precision to ensure perfect edge quality. The long life die cutting tool consists of multiple dies that enable several lids to be punched per stroke. Various lid shapes, formats and embossing patterns are possible.