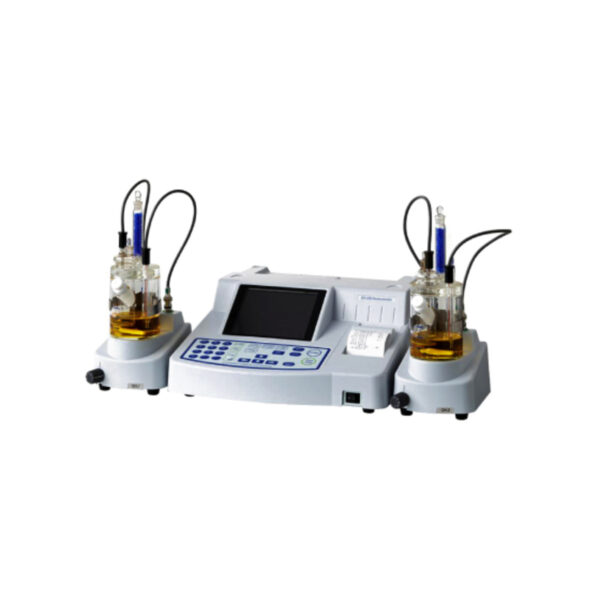

The CA-31 is equipped with a 5.7-inch color LCD touch panel which enables the user to operate practically manual-free, and all necessary information visible in one view.

Users can choose between a conventional 2-solution setup with fritted …

The CA-31 is equipped with a 5.7-inch color LCD touch panel which enables the user to operate practically manual-free, and all necessary information visible in one view.

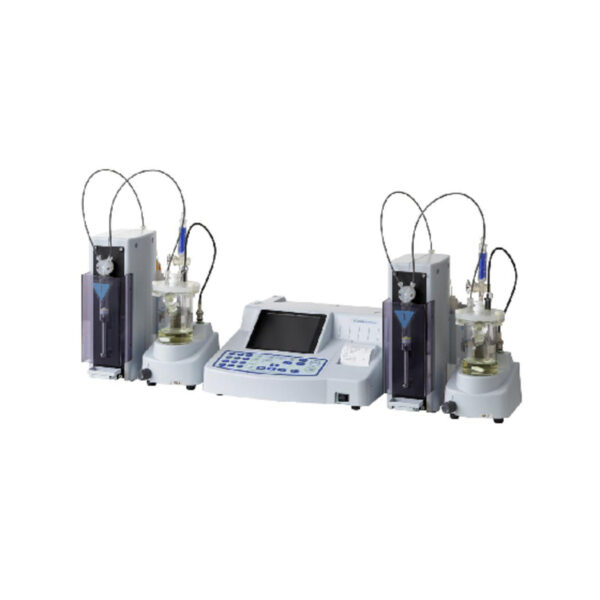

Users can choose between a conventional 2-solution setup with fritted cathode solution cell, or a single solution configuration with fritless cathode. Optional reagent dispensing system can be utilized with the fritless cathode solution cell and automate the replacement of reagent.

Numerous vaporizers from the Mitsubishi product line-up can be connected to the CA-31 to accommodate difficult to dissolve samples such as powders, pellets, pastes, lubricants, etc. By connecting Mitsubishi’s model VG-200 to CA-31, liquefied gas samples can also be measured easily.

PC software TV-31 will enable users to collect measurement results from CA-31 and prepare reports with titration charts, parameters, calculation formula, etc. in Microsoft Word® or Excel® format. A USB keyboard can be connected to the CA-31 for easier input of sample names. For users who prefer not to use the touch panel, it is possible to control all functions of the instrument from the USB keyboard.

This versatile CA-31 is not just a valuable lab equipment, but also best suited for use in the field. With optional battery and carrying case, the instrument can be carried to and used in any location in the field, wherever the sampling is being done.

The instrument can be purchased together with Mitsubishi’s Aquamicron® series of Karl Fischer reagents ranging from conventional 2-solution type, single solution type for fritless cell, and special formulas for oils and ketones. These reagents are developed together with the instruments for the best combined performance.