Ecoclean – Aqueous Cleaning Solutions

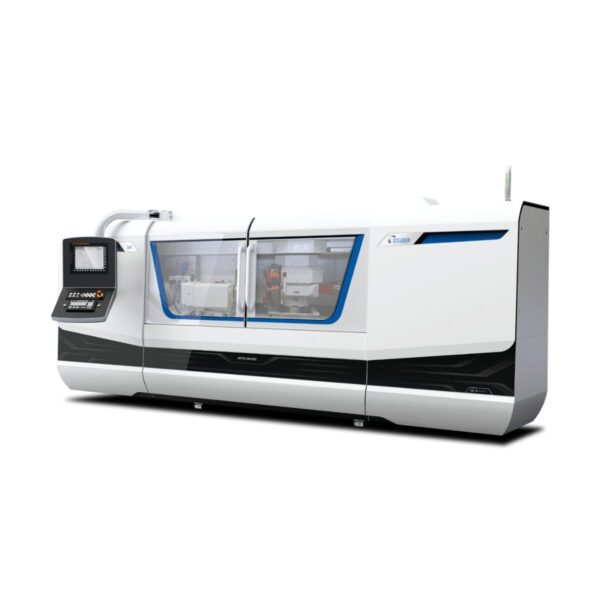

Today environmentally friendly aqueous cleaning has taken on the most important role for the intermediate and final cleaning of parts. They tend to be preferred if a large quantity has to be cleaned and/or fine and finest cleaning has to be carrie…

Today environmentally friendly aqueous cleaning has taken on the most important role for the intermediate and final cleaning of parts. They tend to be preferred if a large quantity has to be cleaned and/or fine and finest cleaning has to be carried out.

Cleaning systems for aqueous cleaning are available as flow-through spray units, single-chamber and multi-chamber systems. To attain a sufficient level of cleaning we integrate mechanical applications into the system, such as ultrasonics or injection flood washing, for example.