Solidfog – Disinfection – DosyMist XL

The DosyMist XL® is a stand-alone VH2O2 generator designed for the bio-decontamination of large areas. These units can be remotely controlled and synchronised with other equal units via facility management s...

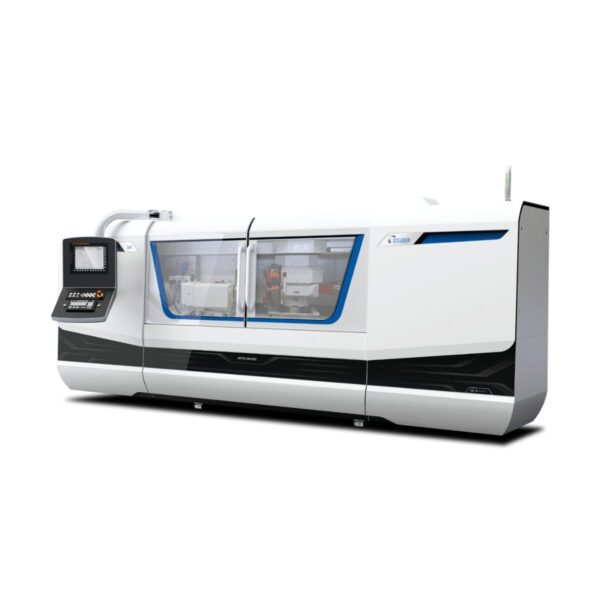

The DosyMist XL® is a stand-alone VH2O2 generator designed for the bio-decontamination of large areas. These units can be remotely controlled and synchronised with other equal units via facility management systems.

The technical features are specifically designed to meet the requirements of the pharmaceutical industry so it is possible to carry out cycle development and process validation quite easily and in relatively short time.