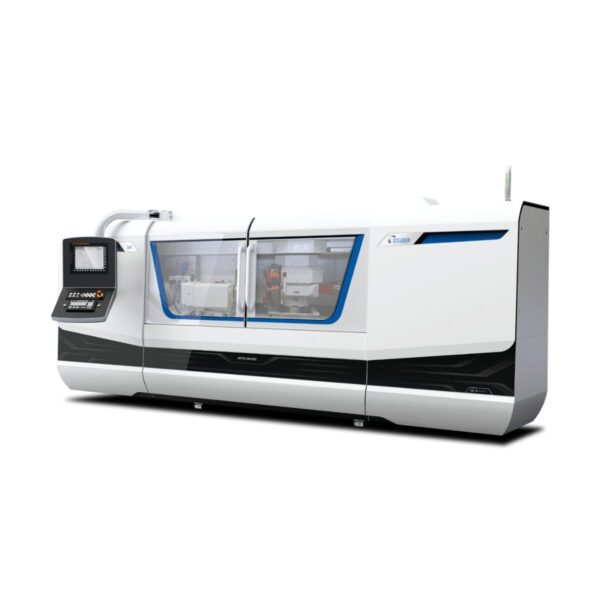

BigRep – 3D Printer – BigRep STUDIO

The BigRep STUDIO, we introduce a workhorse printer that brings a new dimension to large-scale 3D printing. The industrial-grade quality machine has a print volume of 500x1000x500 mm. (WxDxH) that enables continuous printing of large objects in a space-saving package. Fitting easily through doors, the size of the STUDIO is optimal for setting up the printer in all workspaces.

The dual extruder equipped with two 0.6 mm. hot ends has been specially designed for speed and precision. The direct-drive all-metal hot end allows for printing of a larger variety of high-performance filaments.

Technical Specification

| Build volume | x 1000 y 500 z 500 mm. |

| Layer height resolution | 100-500 microns |

| Acceleration | Up to 600 mm./s |

| Printer weight | Approx. 350 Kg. |

| Extruder | Dual extruder Equipped with two 0.6 mm. hot ends |

| Printing technology | FFF – Fused-Filament-Fabrication (FDM) |

Key Features

The ergonomic design.

- Raised for maximum user comfort, the BigRep STUDIO stands at an ideal height for everyday use. Keeping everything compact and accessible, two filament spools can be held below the printer, alongside additional storage space.

The print head.

- The direct drive extruder with two 0.6 mm. hot ends enables printing using industrial materials at maximum speed and precision. Its innovative print head was specially designed to achieve a high level of detail for large-scale print projects, allowing for a layer height of as little as 0.1 mm.

The print bed.

- Preparation time is significantly reduced fo all print projects, with the print bed reaching an optimal adhesion temperature of 60°C in just 10 minutes. Distance from the print bed can be continually calibrated, allowing for maximum flexibility and control over print levels.

The slim build.

- The new BigRep ONE features a build volume of 1005x1005x1005 mm. (WxDxH). With a capacity of over one cubic meter, the new BigRep ONE provides the largest FFF build volume currently available on the international market.

The slide walls.

- The STUDIO’s side-wall housing for increased safety, including auto-pause of print jobs upon opening. The semi-transparent doors enable users to visually monitor the printing process and slide back to provide easy access to the print bed.

The graphical user interface.

- The new intuitive user interface on touch panel PC enables many new features, such as remote load, check print progress via webcam, change print parameters, resume print after power failure, and many more.

BigRep STUDIO: Fast & Precise Large Industrial 3D Printer

Key Industries

- Automotive

- Machinery & Manufacturing

More Products

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep…