PBT Works – MiniSWASH

This machine is a budget solution for anyone who does not expect to clean PCBAs on daily basis. Typically Research and Development centres, prototyping, start-ups and very low volume producers would find this machine sufficient to achieve great results.

Application: Standard SMD Assemblies. Capacity: Small Volume Contamination Solubility: Easy to Moderate

Key Features

- Uses self- rinsing cleaning agents – no waste water problems from rinse

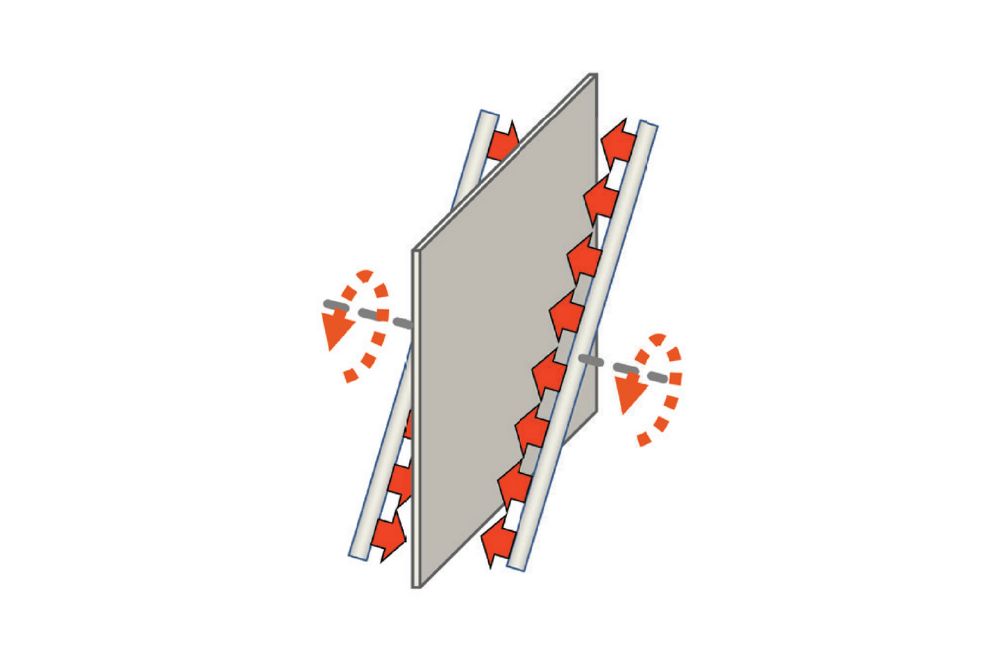

- Motor-driven spray-arms rotate simultaneously. Cleaning without risk of damage even to very thin and fine stencil

- Safety clutch and rotation monitoring of spray manifolds assures safe process and protection of stencil against damage from incorrectly placed stencils

- Spray chamber equipped with special automatically controlled exhaust/inlet air flaps. Hermetically closed during spray

- Efficient drying with hot air circulation and controlled ventilation through exhaust/inlet air flaps

- Compact design with very small floor space requirement

- Easy transport even through 80 cm doors

Technical Specifications

| MiniSWASH I | MiniSWASH II (open loop) | MiniSWASH II (closed loop) | MiniSWASH III | ||

| Number of cleaning phases | 2 | 3 | 3 | 3 | |

|---|---|---|---|---|---|

| Washing, heating | max. 60 °C | max. 60 °C | max. 60 °C | max. 60 °C | |

| Rinsing | N | Tap water | DI water | DI water | |

| Drying | max. 90 °C | max. 90 °C | max. 90 °c | max. 90 °c | |

| Mechanical filtration (Cleaning) | 20″, 5 m | 20″, 5 um | 20″, 5 um | 20″, 5 um | |

| Mechanical filtration (Rinsing) | N | 10″, 5 um | 10″, 1 um 10″, 5 um | 10″, 1 um (10″, 5 um) | |

| Chemical filtration (1st, Rinse loop) | N | N | Activated carbon, Mixbed | Activated carbon, Mixbed | |

| Machine dimensions WxL× Hmm W-left/right, L-front/rear | 1600 × 800 × 1200 mm height 1600 mm with exhaust ventilator or signal tower | 1600 × 800 × 1200 mm height 1600 mm with exhaust ventilator or signal tower | 1600 × 1400 × 1200 mm height 1600 mm with exhaust ventilator or signal tower | 1600 × 1400 × 1200 mm height 1600 mm with exhaust ventilator or signal tower | |

| Machine weight (without liquid) | 220 kg | 250 kg | 350 kg | 450 kg | |

| Maximum power input | 5,3-9,4 kVA | 10,2-10,6 kVA | 10,2-10,6 kVA | 10,2-10,6 kVA | |

| Machine noise level | LAeg <70 dB | LAeg <70 dB | LAeg <70 dB | LAeg <70 dB | |

| For further details, please refer to enclosed brochure. | |||||

Key Features

Cleaning Technology

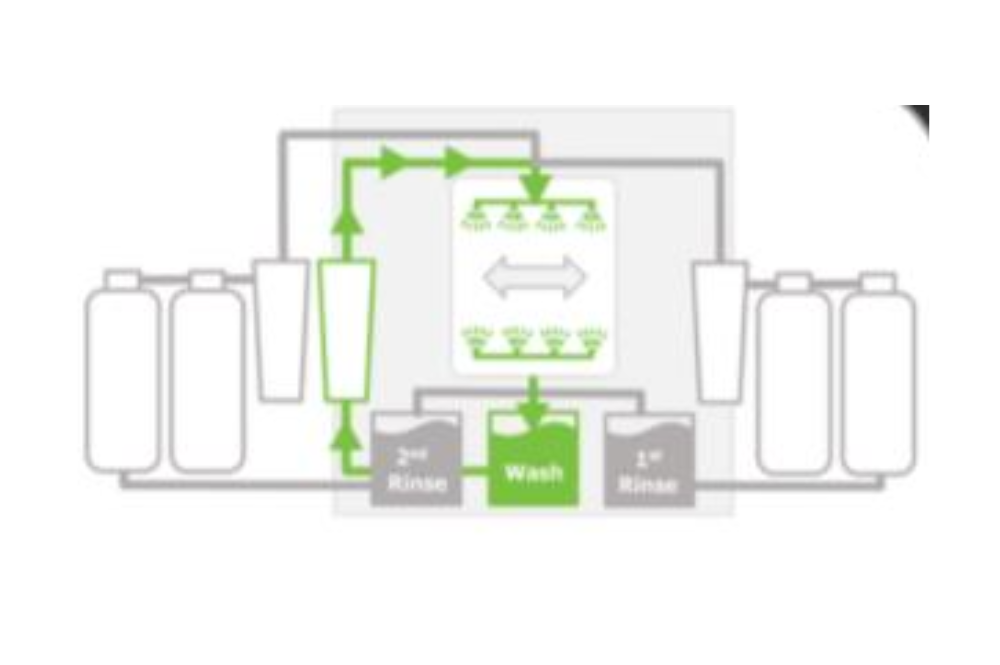

Cleaning quality requires perfect filtration and minimal cross contamination. Every PBT cleaning machine uses separated closed loop with dedicated pump and filtration system for each individual process step.

Wash

Machine washes parts by rotating spray system with the water based cleaning agent in a fully closed loop through complete mechanical filtration.

First Rinse

Machine performs first rinse down to required conductivity level using 16L carbon and mixbed filters.

Second Rinse

Machine performs second rinse with high purity deionized water down to the required conductivity. It reclaims water continuously through 25L carbon and mixbed filters.

Dry

Machine dries parts by convection hot air oven system.

Capacity

MiniSWASH integrated slide-in clamping system holds one PBT standard cleaning frame.

Single Set

For small volume cleaning of any-size PCBAs or mechanical parts in baskets.

Process Control

Cleaning process is sensitive to many variables.

Rotating Spray

Rotating spray offers very good cleaning results. Constant speed synchronized rotation assures great results repeatability.

Rotating Air Knife

Air Knife removes droplets and transfers heat directly to the parts, which significantly accelerates drying.

Adaptive Rinse Control

The rinse water conductivity is monitored by PBT Works conductivity sensor. Machine automatically adjust rinse time according to water quality values.

Chemical Filtration

Machine has 2-stage closed loop rinse water filtration. Compact solution for small volume cleaning.

High Performance Cleaning

Perfect result of PCBA cleaning requires short but powerful spray technology and rapid but thorough drying.

Liquid Pressure Monitoring

The pressure on the spray nozzles is continuously monitored by the control system. Values out of range typically indicates mechanical filter to be exchanged, or nozzles to be reviewed.

Programming and Data Capture

Perfect cleaning result requires detailed programing, quick visual and parametric evaluation of the entire process.

Basic Frame for PCBA

Standard PBT clamping frame for PCBA cleaning. Allows simple reloading directly on the machine.

PCBA Slide-In Slots

Special plastice slide-in slots for quick reloding. Perfect for high volume cleaning of the same sized PCBAs.

PCBA Horizontal Bars with Springs

Special springs for clamping PCBAs with perfectly balanced grip force.

PCBA Basket

Various sizes of precise welded baskets. Basic positioning solution for any part to clean.

Clamping

Usable Space

Maximal usable space for cleaned parts including specifically selected clamping

PBT Works MiniSWASH

MiniSWASH – Rotating Air Knife Technology

MiniSWASH – Rotating Direct Spray Technology

Key Industries

- Semiconductor, Solar & Electronics

More Products

PBT Works s.r.o. is a new name with old history. PBT Works have manufactured our first cleaning machines and simple…