Nutek – High Speed Mini Loader

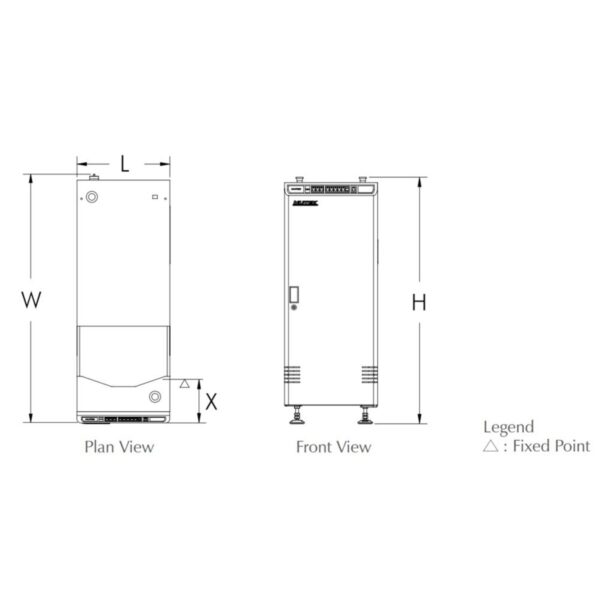

This unit is used for loading of substrates, leadframes or carriers.

Key Features

- Applicable to various substrates, leadframes or carriers

- “Servo contr...

This unit is used for loading of substrates, leadframes or carriers.

Key Features

- Applicable to various substrates, leadframes or carriers

- “Servo control” lifting motion

- High speed and precise indexing

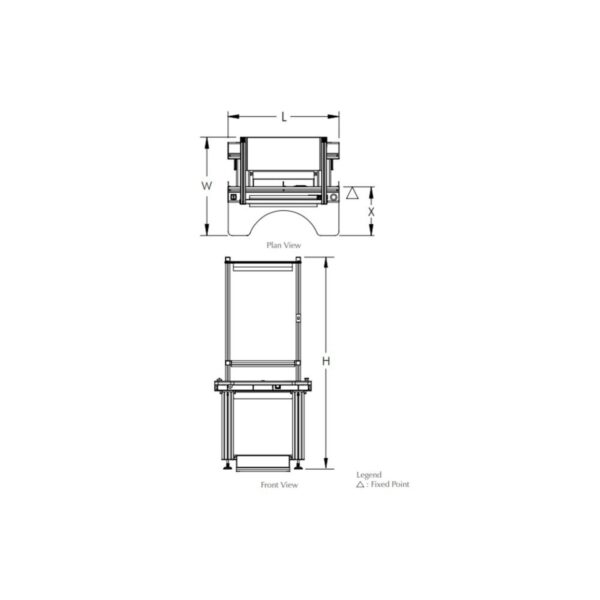

- Machine size depends on the type of magazine used

- Stores up to 10 different types of magazine dimensions

- Stainless steel magazine guide

- Pneumatic pusher’s pressure regulated

- Easy loading or unloading of magazines

- User friendly touch screen panel

- SMEMA compatible