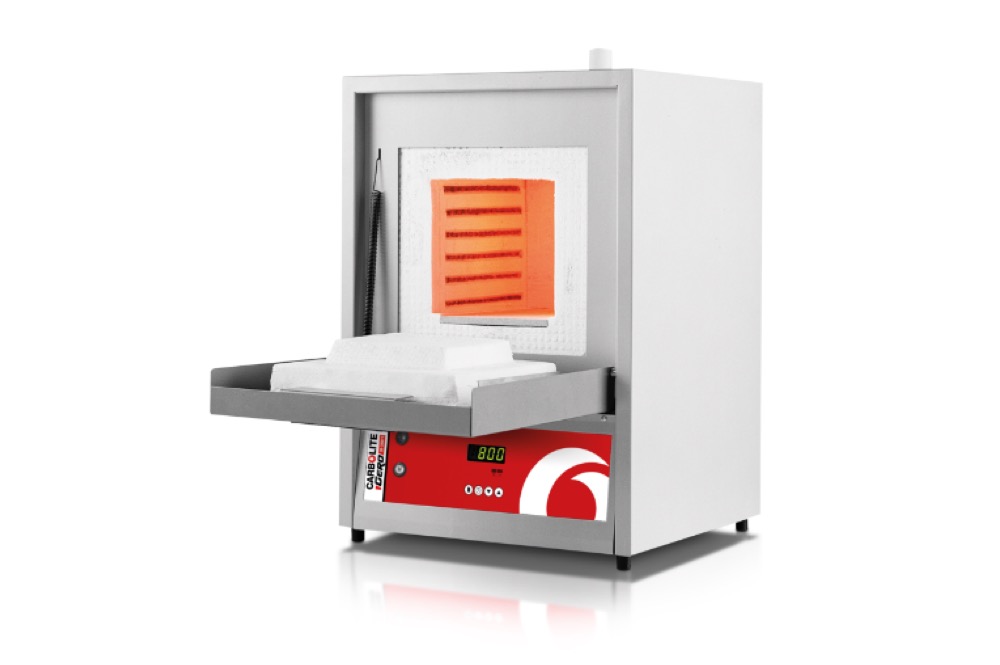

Carbolite Gero – Laboratory Chamber Furnace

Carbolite Gero’s extensive chamber furnace range has a maximum operating temperature of 1800°C and chamber capacities up to 725 liters. They are suitable for a variety of laboratory, pilot scale and industrial applications. Although there is flexibility in size and temperature, if the application requires the use of modified atmosphere (above 1100°C) or vacuum then a furnace from Carbolite Gero’s tube furnace range should be selected.

Available Models

Technical Specifications

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Max. continuous operating temp. [°C] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External H x W x D [mm] | Temperature uniformity of ±5°C within H x W x D [mm] | Volume [litres] | Max. power [W] | Holding power [W] | Thermocouple type | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ELF 11/6 | 1100 | 28 | 1000 | 165 x 180 x 210 | 580 x 410 x 420 | 125 x 140 x 140 | 6 | 2000 | 900 | K | 24 |

| ELF 11/14 | 1100 | 43 | 1000 | 210 x 220 x 310 | 630 x 450 x 520 | 170 x 180 x 205 | 14 | 2600 | 1300 | K | 31 |

| ELF 11/23 | 1100 | 26 | 1000 | 235 x 255 x 400 | 715 x 505 x 690 | 195 x 215 x 305 | 23 | 5000 | 1550 | K | 52 |

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Max. continuous operating temp. [°C] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External H x W x D [mm] | Dimensions: External with door open H x W x D [mm] | Temperature uniformity of ±5°C within H x W x D [mm] | Volume [litres] | Max. power [W] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| Standard Chamber Furnaces | ||||||||||

| CWF 11/5 | 1100 | 47 | 1000 | 135 x 140 x 250 | 585 x 375 x 485 | 800 x 375 x 485 | 85 x 90 x 110 | 5 | 2400 | 30 |

| CWF 11/13 | 1100 | 90 | 1000 | 200 x 200 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | 120 x 120 x 185 | 13 | 3100 | 47 |

| CWF 11/23 | 1100 | 36 | 1000 | 235 x 245 x 400 | 705 x 505 x 675 | 990 x 505 x 675 | 155 x 165 x 285 | 23 | 7000 | 68 |

| CWF 12/5 | 1200 | 51 | 1100 | 135 x 140 x 250 | 585 x 375 x 485 | 800 x 375 x 485 | 85 x 90 x 125 | 5 | 2400 | 30 |

| CWF 12/13 | 1200 | 80 | 1100 | 200 x 200 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | 120 x 120 x 200 | 13 | 3100 | 47 |

| CWF 12/23 | 1200 | 45 | 1100 | 235 x 245 x 400 | 705 x 505 x 675 | 990 x 505 x 675 | 155 x 165 x 325 | 23 | 7000 | 68 |

| CWF 12/65 | 1200 | 40 | 1100 | 278 x 388 x 595 | 885 x 780 x 945 | 1245 x 780 x 945 | 178 x 288 x 455 | 65 | 14000 | 165 |

| CWF 13/5 | 1300 | 75 | 1200 | 135 x 140 x 250 | 585 x 375 x 485 | 800 x 375 x 485 | 85 x 90 x 150 | 5 | 2400 | 30 |

| CWF 13/13 | 1300 | 115 | 1200 | 200 x 200 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | 120 x 120 x 225 | 13 | 3100 | 47 |

| CWF 13/23 | 1300 | 55 | 1200 | 235 x 245 x 400 | 705 x 505 x 675 | 990 x 505 x 675 | 155 x 165 x 340 | 23 | 7000 | 68 |

| CWF 13/36 | 1300 | 47 | 1200 | 250 x 320 x 450 | 810 x 690 x 780 | 1105 x 690 x 780 | 1105 x 690 x 780 | 36 | 9000 | 100 |

| CWF 13/65 | 1300 | 45 | 1200 | 278 x 388 x 595 | 885 x 780 x 945 | 1245 x 780 x 945 | 178 x 288 x 520 | 65 | 14000 | 165 |

| Burn-off Chamber Furnaces | ||||||||||

| CWF-B 11/13 | 1100 | 103 | 1000 | 200 x 200 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | n/a | 13 | 3100 | 47 |

| CWF-B 12/13 | 1200 | 130 | 1100 | 200 x 200 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | n/a | 13 | 3100 | 47 |

| Chamber Furnace with Integral Balance | ||||||||||

| CWF-BAL 11/21 | 1100 | 60 | 1000 | 215 x 245 x 400 | 705 x 505 x 675 (400 x 170 x 500) | 990 x 505 x 675 | n/a | 21 | 7000 | 80 |

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Max. continuous operating temp. [°C] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External H x W x D [mm] | Temperature uniformity of ±5°C within H x W x D [mm] | Volume [litres] | Max. power [W] | Holding power [W] | Thermocouple type | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RWF 11/5 | 1100 | 10 | 1000 | 130 x 160 x 250 | 585 x 375 x 325 | 800 x 375 x 325 | 5 | 2750 | 680 | K | 28 |

| RWF 11/13 | 1100 | 11 | 1000 | 195 x 210 x 325 | 655 x 435 x 610 | 905 x 435 x 610 | 13 | 5000 | 1200 | K | 45 |

| RWF 11/23 | 1100 | 13 | 1000 | 220 x 260 x 400 | 705 x 505 x 675 | 990 x 505 x 675 | 23 | 9100 | 1800 | K | 65 |

| RWF 12/5 | 1200 | 12 | 1100 | 130 x 160 x 250 | 585 x 375 x 485 | 800 x 375 x 485 | 5 | 2750 | 820 | R | 28 |

| RWF 12/13 | 1200 | 13 | 1100 | 195 x 210 x 325 | 655 x 435 x 610 | 655 x 435 x 610 | 13 | 5000 | 1450 | R | 45 |

| RWF 12/23 | 1200 | 15 | 1100 | 220 x 260 x 400 | 705 x 505 x 675 | 990 x 505 x 675 | 23 | 9100 | 2100 | R | 65 |

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Max. continuous operating temp. [°C] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External H x W x D [mm] | Temperature uniformity of ±5°C within H x W x D [mm] | Volume [litres] | Max. power [W] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|

| VCF 12/5 | 1200 | 102 | 260 x 155 x 130 | 660 x 530 x 405 (Floor-standing) | 5 | 2500 | 900 | R | 50 |

| VCF 12/10 | 1200 | 138 | 365 x 180 x 155 | 765 x 555 x 430 (Floor-standing) | 10 | 3000 | 1200 | R | 60 |

| VCF 12/23 | 1200 | 125 | 450 x 250 x 200 | 850 x 600 x 500 (Floor-standing) | 23 | 6000 | 2500 | R | 130 |

| VCF 12/100 | 1200 | 150 | 600 x 410 x 410 | 1100 x 930 x 950 (Floor-standing) | 100 | 15000 | 6000 | R | 200 |

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External with door open H x W x D [mm] | Volume [litres] | Holding power [W] | Max. power [W] | Thermocouple type | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|

| RHF 14/3 | 1400 | 33 | 120 x 120 x 205 | 655 x 435 x 610 (905) (Bench-top) | 3 | 1900 | 4500 | R | 42 |

| RHF 14/8 | 1400 | 22 | 170 x 170 x 270 | 705 x 505 x 675 (990) (Bench-top) | 8 | 3200 | 8000 | R | 64 |

| RHF 14/15 | 1400 | 35 | 220 x 220 x 310 | 810 x 690 x780 (1105) (Bench-top) | 15 | 2900 | 10000 | R | 125 |

| RHF 14/35 | 1400 | 38 | 250 x 300 x 465 | 885 x 780 x 945 (1245) (Benchtop) | 35 | 6000 | 16000 | R | 179 |

| RHF 15/3 | 1500 | 45 | 120 x 120 x 205 | 655 x 435 x 610 (905) (Bench-top) | 3 | 2000 | 4500 | R | 46 |

| RHF 15/8 | 1500 | 40 | 170 x 170 x 270 | 705 x 505 x 675 (990) (Bench-top) | 8 | 3500 | 8000 | R | 61 |

| RHF 15/15 | 1500 | 46 | 220 x 220 x 310 | 810 x 690 x 780 (1105) (Bench-top) | 15 | 3000 | 10000 | R | 125 |

| RHF 15/35 | 1500 | 46 | 250 x 300 x 465 | 885 x 780 x 945 (1245) (Bench-top) | 35 | 6200 | 16000 | R | 178 |

| RHF 16/3 | 1600 | 42 | 120 x 120 x 205 | 655 x 435 x 610 (905) (Bench-top) | 3 | 2300 | 4500 | R | 42 |

| RHF 16/8 | 1600 | 35 | 170 x 170 x 270 | 705 x 505 x 675 (990) (Bench-top) | 8 | 4000 | 8000 | R | 61 |

| RHF 16/15 | 1600 | 58 | 220 x 220 x 310 | 810 x 690 x 780 (1105) (Bench-top) | 15 | 3500 | 10000 | R | 140 |

| RHF 16/35 | 1600 | 113 | 250 x 300 x 465 | 1530 x 900 x 1020 (1885) (Floor-standing) | 35 | 7000 | 16000 | R | 270 |

| CGH Model | Max. temp. [°C] | Heat-up time [mins] | Dimensions: Usable chamber H x W x D [mm] | Dimensions: External with door open H x W x D [mm] | Volume [litres] | Max. power [W] | Thermocouple type | Weight [kg] |

|---|---|---|---|---|---|---|---|---|

| HTF 17/5 | 1700 | 50 | 158 x 150 x 225 | 565 x 830 x 650 (850) (Bench-top) | 5 | 4050 | B | 109 |

| HTF 17/10 | 1700 | 44 | 232 x 200 x 225 | 565 x 830 x 650 (850) (Bench-top) | 10 | 5920 | B | 133 |

| HTF 18/4 | 1800 | 65 | 140 x 140 x 190 | 565 x 830 x 650 (850) (Bench-top) | 4 | 4650 | Pt20%Rh / Pt40%Rh | 115 |

| HTF 18/8 | 1800 | 56 | 210 x 190 x 190 | 565 x 830 x 650 (850) (Bench-top) | 8 | 6200 | Pt20%Rh / Pt40%Rh | 128 |