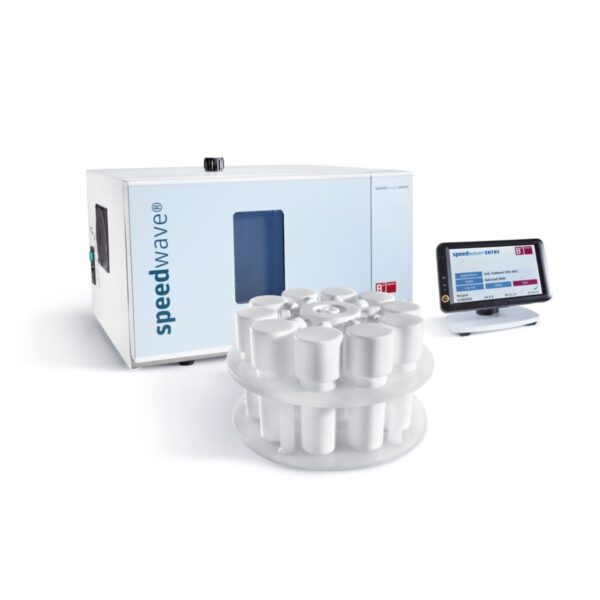

Berghof – Microwave Digester – Speedwave Entry

The speedwave ENTRY shows its strengths in application areas where cost efficiency is a key issue. It is therefore used in routine analysis in environmental, food and pharmaceutical applications. Easy to operate, yet cost-efficient and safe.

The speedwave ENTRY shows its strengths in application areas where cost efficiency is a key issue. It is therefore used in routine analysis in environmental, food and pharmaceutical applications. Easy to operate, yet cost-efficient and safe.